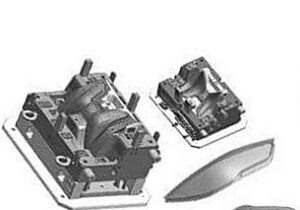

Injection Mould Pictures

Description

An injection mold, also known as an injection molding tool or die, is a specialized tool used in the injection molding process to produce plastic parts. It is a custom-made device that is designed to shape molten plastic material into a specific form and allow it to cool and solidify within the mold cavity.

The injection mold consists of two main halves, the core and the cavity, which fit together to form the desired shape of the finished part. The cavity is the void in the mold that defines the external shape and features of the part, while the core creates the internal features, such as holes or hollow sections. These halves are precision-machined from hardened steel or aluminum to withstand the high pressure and temperature of the injection molding process.

The injection mold also includes various additional components, such as slides, inserts, ejector pins, and cooling channels. Slides and inserts are movable parts that create additional features or undercuts in the part design. Ejector pins help in ejecting the finished part from the mold once it has solidified. Cooling channels are incorporated into the mold to circulate coolant or water, enabling efficient cooling and solidification of the molten plastic.

The design of an injection mold depends on the specific requirements of the part being manufactured. It involves careful consideration of factors such as part geometry, material properties, draft angles, gate locations, and venting. The mold design should ensure proper flow of molten plastic, minimize any defects or imperfections, and allow for easy ejection of the part.

Injection molds are typically produced by skilled toolmakers or mold manufacturers using advanced CNC (Computer Numerical Control) machines and other precision machining techniques. The process involves several steps, including mold design, material selection, machining, and surface finishing. The complexity and size of the mold can vary depending on the part’s requirements and the production volume.

Once the injection mold is ready, it is mounted onto an injection molding machine. The machine melts plastic material, usually in the form of pellets, and injects it into the mold under high pressure. The molten plastic fills the mold cavity, taking the shape of the mold’s internal surfaces. After cooling and solidification, the mold is opened, and the finished part is ejected.

DJmolding is a world-class plastic injection molding & mould manufacturer meeting European and American standards, especail be good at automotive parts industry. 13+ years Specializing manufactures a serial of automotive moulds, including HVAC mould, bumper mould, auto lamp mould, automotive exterior/interior mould, washer tank mould, instrument panel mould, fender mould, bi-injection mould, door panel mould., etc.

DJmolding has grown into a superior mold manufacturer with a strong engineering team. Engineering work includes not only mold designs, but also mold feasibility, mold flow, product design expertise and prototyping services. These allow the most efficient mold strategies to be developed for our customers.

Read more: https://www.djmolding.com/injection-mould-pictures/

There are no reviews yet.